Crews picked concrete precast girders as heavy as 93.5 tons from a deteriorated bridge over the Williams River and transferred them to the first of two Vermont Interstate 91 bridge replacements, illustrating a unique approach that took a lot of coordination and planning.

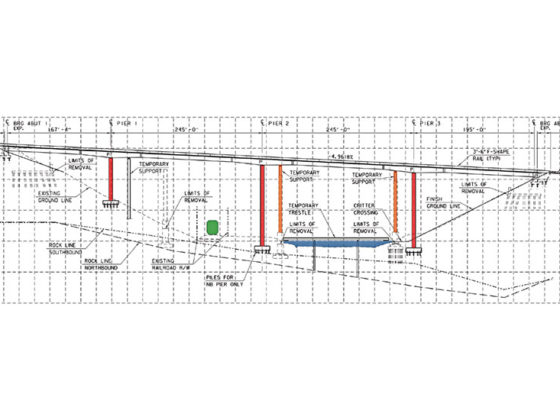

The $50-million I-91 Rockingham Bridge project will replace two aging steel truss bridges with a four-span spliced precast concrete girder structure—a first in Vermont. The new bridges will be 6 ft 3 in. wider than the old one, with two 12-ft travel lanes, one 4-ft shoulder and a 10-ft breakdown lane. The project is expected to finish by September, according to the Vermont Agency of Transportation (VTrans).

Crews picked girders off the existing bridge and placed them on the new bridge approximately 100 ft above the cranes sitting on a work trestle between the structures, says John Phillips, project manager for Reed & Reed, the design-build team’s general contractor. “The process of erecting and splicing precast girders in midair has been the biggest challenge,” he says. “Good planning helps, but at the end of the day, it takes a lot of hard work from our dedicated and skilled crew.”

Carrying an average of 7,000 vehicles daily, the 60-year-old steel deck truss twin bridge, locally called the High Bridges, was in “poor condition,” says Carolyn Cota, Vtrans project manager. “The deck had been patched and joint work had been done, but it had not been rehabilitated.”

Unique Design and Methods

One unique design feature of the four-span bridge structures are the unbalanced span lengths, ranging from 167 ft to 245 ft. The overall bridge length is about 852 ft. “Going with unbalanced span lengths allowed our contractor to utilize the existing piers as temporary supports during erection for our haunched girders,” says Tom French, senior project manager and engineer of record for HDR, the project’s lead designer.

Girder installation began in 2018, two years after the bridge replacement project began. Delivering the oversized beams to the offload area near the bridge was a coordinated effort between Reed & Reed, JP Carrara and Windham County Sheriff officers, who conducted rolling road blocks to allow the team to offload the girders from the existing two-lane bridge, carrying both northbound and southbound I-91 traffic, in 20-minute gaps.

Initially this took more than 20 minutes, but as they improved, “they were right on the 20-minute mark,” French says. “They looked like a NASCAR team with more than a dozen people converging … with chains to hook and unhook.”

This process was repeated 35 times to place the 35 precast pieces of three types of girders—96 ft long by 6 ft 6 in. and up to 10 ft high, 187,000-lb haunched ones of varying depth that are set on piers and drop-in sections and end girders weighing 1,200 lb per linear ft and varying in length from 120 ft up to 147 ft from end to end.

JP Carrara and Sons Inc. of Middlebury, Vt., delivered the first precast girder by truck in June 2018. Before offloading the girders, the crews installed two big rubber bearings designed to maximize economy, French says. “The contractor had to maintain an elevation tolerance of 1/16th of an inch between the bearings, so it was difficult to fabricate the concrete under it to the tolerance needed,” French says. The innovative solution was to mount those bearings before placing the girders on temporary supports and flood them with grout, allowing the team to set the girders exactly in the right location.

Working in Tight Constraints

In addition to traffic management, the team’s construction engineer had to validate whether they could physically operate the cranes within inches on boom clearance with the old bridge. “Likewise, when we set the girders on the new bridge, in many cases the clearance of the boom was within inches of the girders,” Phillips says. “In some cases, we had to lower the beam slightly, reposition the crane slightly, pick it back up and set it in its final location. And several times, the location set on the existing bridge could not be the same as on the new bridge.”

To deal with extremely tight tolerances, construction engineer McNary Bergeron & Associates modeled the upload and erection process to achieve precision planning for crane positioning with proper boom clearances.

McNary’s girder erection plan included temporary girder supports for pier girders and temporary strongback connections for the drop-in and abutment girders “needed to support the superstructure until the cast-in-place girder splices and diaphragms could be placed and post-tensioning system installed,” Phillips says.

In mid-February, after the last of 35 girders were lifted into their final locations on the foundations of the second bridge, crews performed spliced girder placements, filling six 2-ft gaps with concrete to connect the seven pieces for each beam.

Before removing temporary supports in March, crews will install 6/10-in.-dia post-tensioning strands, which makes the superstructure self-supporting. “Bundling 19 strands together into a tendon of the spliced girder holds the bridge together,” French explains.

Each of the bridge’s five girders has 57 strands for a total of 285 strands. Using a strand pusher, crews insert the post-tension steel strands, a cable-like wire rope, that stretches 850 ft through the middle of the concrete girders from one end of the bridge to the other. “By using post-tensioning, you end up with 2 million pounds of compression,” French says.

Expediting Construction

To expedite southbound bridge construction in late 2018, crews began building the foundation in a portion of the pier shafts beneath the old bridge while it was still in use. Phillips says working underneath an operational bridge saved the equivalent of nearly 1.5 months, but was complicated. “You have to think about the bridge above,” he says. “Using smaller cranes and demo work is more challenging.”

For the first bridge, crews removed the steel superstructure, tipped the piers over and let them fall on the ground. “But for the second bridge, we had to take the piers apart in pieces, design a picking system so we could hook onto them with the crane, cut them, then pick the concrete off, lower it and demo it,” Phillips says.

Innovative Design Features

VTrans incorporated one contract requirement related to pier slenderness that was more stringent than requirements by the American Association of State Highway and Transportation Officials, French says. “To solve this, we employed two bearings per girder at each pier to increase rotational stiffness at the pier caps,” he says.

This project also required managing the 130-ft piers as “mass concrete” placements, Phillips says. The team had to monitor temperature during the concrete curing and install cooling tubes that allowed crews to pump cold water through the pier shaft to keep the temperature differential between the core and exterior within specified limits.

To achieve a 100-year service life, the team used stainless steel reinforcing in the pier caps and deck and concrete highly resistant to chloride penetration, Phillips says. The team also conducted chemical analysis of soils so that the piles could be upsized to account for 100 years of degradation. The 15-in. H-piles were driven into the ground at a depth ranging from 10 ft to 120 ft.

The design strength of the ready-mix concrete for the piers (3,500 psi) and girders (9,000 psi) was achieved within the expected 28 days, and in many cases, one to two weeks,” Phillips says.

Since the bridge only has two joints on each end, the team developed an innovative concrete landing trough on the abutment face that captures deck water if one of those joint fails and filters it back into the ground. “The trough prevents a leaky joint from depositing water into the bridge seat or bridge bearing devices,” French says. “We didn’t want to have our bearings deteriorate prematurely.”

Schedule Challenges

Although the technical challenges of building a spliced precast girder structure are constant, a mild winter helped the team gain time after struggling through a cold, rainy fall. Nevertheless, the project fell two months behind schedule due to delays over approval of a traffic control plan and rain, according to VTrans officials, who note the contract allows for adjustments to completion dates with any extensions evaluated after project completion. Officials also say the contractor will be assessed liquidated damages of $12,500 per day for not meeting the Feb. 5, 2020, substantial completion and $8,500 per day for not completing the project by Sept. 8, 2020. “It is not unusual for four-year projects to run into delays,” says Daryl Bassett, VTrans resident engineer.

Phillips says the contractor has not yet reached substantial completion, but expects to by late summer.

After a slow start, Phillips said the project team worked hard to regain time lost by adjusting pier construction sequencing as well as completing girder erection and post-tensioning this winter. “Our goal is to finish work on the superstructure in March,” Phillips says, “then step back for a few weeks before doing site preparation in April to finish the bridge by next season.”

Maintenance Cost Savings

Replacing the aging bridge with a 100-year-service-life concrete structure is expected to save money on painting and other maintenance, says David Peterson, design engineer with VTrans. But fabricating the huge and ultra-heavy I-beam girders of varying depth, from 6.5 ft up to 10 ft and 4 ft wide and weighing from 145,000 lb (72.5 tons) for an end girder up to 225,000 lb (112.5 tons) for a haunch girder on a truck, poses new challenges for the fabricator, he says. “These are some of the bigger pieces the precasters have ever fabricated.”

The girders also have thin webs with large ducts that led to some “consolidation issues,” he says. For future projects, he expects the agency “will work alongside the designer and fabricator to fine-tune structural design and detailing in hope of simplifying fabrication and erection issues.”

To this point, Kristin Higgins, VTrans structures manager, says the benefit of the design-build project is “that contractors bring innovation through their solutions. It’s a way to investigate the pros and cons of any bridge system and put that in our toolbox for the future.”